August 31, 2011

By L.P. Brezny

Winchester is making a move in the premium steel shotshell category with the introduction of Winchester Blind Side, a non-toxic option featuring hexagon-shaped pellets.

Winchester is making a move in the premium steel shotshell category with the introduction of Winchester Blind Side, a non-toxic option featuring hexagon-shaped pellets.

One primary advantage of non-round shot is increased packing density in the hull. Because Winchester Blind Side pellets have six sides, the shot stacks, increasing the pellet count and allowing a larger payload. A basic 12-gauge, 3-inch shotshell holds a maximum of ¹¹â'„â‚„ ounces of round steel shot. The stackable shot of Blind Side allows 1³â'„â‚' ounces of pellets in a 3-inch hull — a stiff payload for an iron shot load.

TESTING VELOCITY

Blind Side has a stated muzzle velocity of 1,400 feet per second. I measured the velocity at 1,351 fps 3 feet from the muzzle using an Oehler Chronotech Model 33. My test barrel was 28 inches long, and the choke was a 40-point Invector-Plus full.

Advertisement

Flat-sided pellets raise the question of faster velocity loss downrange because of added wind drag. Using a 3-inch, No. 2 Blind Side load, I turned to my own self-designed downrange chronograph system to answer the question. Shooting at 40 yards from the muzzle over my armored Chronotech photo screens, the Oehler returned a measured downrange velocity of 634 fps. The calculated reading was based on a modified-choke muzzle velocity measured at 1,354 fps at the time of the downrange velocity test. Standard round No. 2 steel will return close to the same velocity. I say "close" because on any given day, plus varied altitude, air temperature, barometric pressure and wind, the number can increase or decrease. Please also note that muzzle velocity testing is always at 3 feet from the muzzle and slower than the actual muzzle velocity. Winchester states that the new load runs out at 1,400 fps, which agrees with my velocity tests.

PATTERNS AND CHOKES

Advertisement

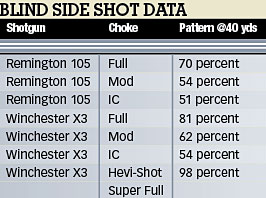

During testing, Winchester Blind Side produced varied patterns with small changes in choke dimensions. When fired through my Remington CTi 105-II in three choke configurations, the level of performance was very different from test rounds through the Invector-Plus choke-tube system in a Winchester Super X3. No. 2 Blind Side printed an average of 81 percent inside of a 30-inch circle at 40 yards based on three test rounds downrange.

Non-round pellets don't generally fly as straight as round pellets. Winchester Ammunition engineers thought out that yes, the shape of the shot had greatly been altered, but each pellet was altered in exactly the same way. Pellets with a uniform design tended to fly true.

The above data table illustrates the full, modified and improved cylinder patterns produced by Winchester Super X3 and Invector-Plus factory choke tubes, and the Remington CTi 105-II shooting the same series of choke sizes in the Remington choke-tube wrapper. Note the different pattern percentage scores. The actual difference downrange was major. Don't assume anything about your choke system, and always put shot on paper before hunting. I also shot the Winchester Super X3 with a Hevi-Shot extended special high-performance super-full choke for an aftermarket choke comparison. That choke was my long-range ace in the hole at 98 percent with a tight core for a three-round average.

MORE PELLETS

A problem associated with steel shot from day one in its development was the fact that when pellet sizes increased, payload space was squeezed. The 3 1/2-inch, 12-gauge shotshell was designed to hold larger pellets to pattern well enough to kill large ducks and geese. Winchester hex-sided pellets allow more steel to fit in the same space. The No. 2 payload in Blind Side 1³â'„â‚'-ounce loads count out to 169 pellets. More pellets in the shell should equate to more pellets hitting the bird.

The new diamond cut wad seems to generate additional positive payload control downrange. Wads were all recovered close to the same place when fired in windless conditions during pattern testing and chronograph velocity work. As previously illustrated, the ability of the payload to print solid patterns is clearly evident. Winchester has used two-piece wads in other non-toxic ammunition in the past, and that design is applied to Blind Side. The primary payload container (shot cup) is separate from the gas seal plastic wad that sits independently under the diamond cut wad.

ENERGY TRANSFER

I employed two test systems to gain understanding of the net effect of hex shot on soft targets downrange. First, I fired test rounds at 40 yards into ballistic gelatin, and then at pinned dead birds. Pellets recovered from a previously harvested and pinned Canada goose, as well as an observed energy channel against ballistic gel, indicated the pellets in Blind Side loads transfer energy to tissue quite well. The "smoke line" in the gel that develops as a temporary expanded wound channel was larger at times as per the first contact point than that found when shooting standard round iron shot loads side by side against hex shot.

Penetration was about the same as standard No. 2 steel. Blind Side was more than adequate to reach vitals, break bones or disrupt the nervous system in even large birds at decoy ranges.

Pinned (dead) waterfowl have been a common learning tool in ballistics. The subject is not going anyplace, can be positioned at exact ranged distances from the muzzle, and measurements can be done in an accurate and timely manner.

Shooting a Remington 870 turkey special with rifle sights, I put 22 pellets of Blind Side No. 2 pellets into a pinned 101/2-pound Canada goose at 40 yards. I was not looking for waterfowl performance patterns, but as many samples with one shot fired as possible for penetration evaluation when I took the bird apart. What I found upon examination was Blind Side No. 2 pellets were a bit light for heavily feathered, large Canada geese. Penetration was adequate in about one-third of the recovered wound channel examples.

I had only 3-inch, No. 2 Blind Side to test, but loads are now available in BB shot and 31/2-inch shells. Goose hunters will welcome larger shot sizes and loads.